Mastering the Art of Cutting Threaded Rods to Perfection

Ah, the humble threaded rod – that unsung hero of the DIY and construction world. Whether you’re a seasoned pro or a weekend warrior, chances are you’ve found yourself in need of a reliable threaded rod cutter at some point. And let me tell you, finding the right tool for the job can make all the difference between a smooth, seamless project and a total headache.

You see, I’ve been there, my friends. I remember the days when I’d try to make do with a hacksaw or a pair of bolt cutters, only to end up with a jagged, uneven cut that made me want to pull my hair out. It was like trying to slice a piece of fresh mozzarella with a dull butter knife – you just end up making a mess and wishing you had the right tool for the task.

But fear not, because today, I’m here to share my hard-earned wisdom on the world of threaded rod cutters. We’re going to dive deep into the ins and outs of these handy tools, from understanding the different types and features to mastering the art of properly sizing your all-thread and rebar. By the time we’re done, you’ll be cutting threaded rods like a pro, and never again will you have to settle for a subpar finish.

Threaded Rod Cutters: What Are They and Why Do You Need One?

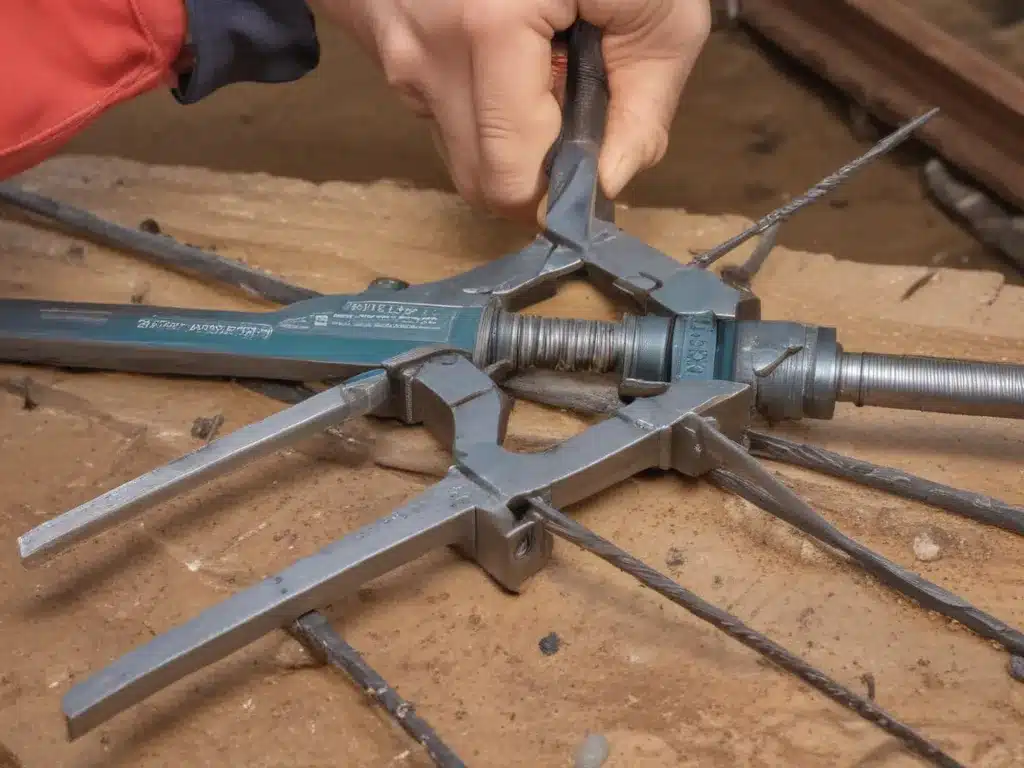

A threaded rod cutter, my friends, is a specialized tool designed to cleanly and precisely cut through various types of threaded rods, including all-thread and rebar. Unlike your typical hacksaw or bolt cutters, these bad boys are engineered to provide a clean, square cut without any burrs or jagged edges.

But why, you ask, would I need a dedicated tool for cutting threaded rods? Well, let me tell you, it’s all about achieving that perfect, professional-looking finish. When you’re working on a project that involves threaded rods, a clean, straight cut is crucial. Anything less and you risk running into all sorts of problems, from threads not lining up properly to the rod itself becoming weakened and prone to failure.

And let’s not forget the sheer frustration of trying to work with a less-than-ideal cut. I mean, have you ever tried to try to screw a nut onto a rod that’s been hacked away with a hacksaw? It’s like trying to fit a square peg into a round hole – it just ain’t happening.

That’s where the threaded rod cutter comes in, my friends. With its precise blades and sturdy construction, these tools make quick work of even the toughest threaded rods, leaving you with a clean, square edge that’s ready to be threaded, bolted, or whatever else your project demands.

Choosing the Right Threaded Rod Cutter: Size Matters

Now, let’s talk about the different types of threaded rod cutters out there and how to choose the one that’s right for your needs. Because, let me tell you, not all threaded rod cutters are created equal, and picking the wrong one can lead to all sorts of headaches.

The first thing you need to consider is the size of the threaded rod you’ll be working with. Threaded rod cutters come in a range of sizes, from tiny little guys that can handle 1/4-inch all-thread all the way up to behemoths that can tackle 1-inch rebar. And trust me, you do not want to try to cut a 1-inch rod with a tool that’s only meant for 1/4-inch – it’s just not going to end well.

So, how do you figure out which size cutter you need? Well, it’s all about measuring that rod and matching it up to the specifications of the tool. Most threaded rod cutters will have a clear size range printed right on the side, so all you have to do is break out the old measuring tape and make sure you’re getting a tool that’s up to the task.

And let me just say, it’s worth taking the time to get this right, because trying to cut a rod that’s too big for your cutter is a recipe for disaster. Best case scenario, you end up with a ragged, uneven cut that’s going to make your life a living hell. Worst case, you could actually damage the tool itself or even put yourself in harm’s way.

So, measure twice, cut once, my friends. Take a good hard look at that threaded rod, figure out exactly what size you need, and then go forth and find the perfect cutter to match. Your future self will thank you, I promise.

Cutting All-Thread vs. Rebar: Different Challenges, Different Approaches

Alright, now that we’ve got the basics of threaded rod cutters down, let’s dive a little deeper and talk about the different challenges you might face when cutting all-thread versus rebar.

You see, while they may look similar on the surface, these two types of threaded rods have some key differences that can really impact how you approach the cutting process. And trust me, you don’t want to be caught off guard and end up with a mangled mess on your hands.

Let’s start with all-thread, shall we? This stuff is typically made from softer materials like mild steel or aluminum, which means it’s generally a bit easier to cut through. The threads are also usually a bit more uniform and consistent, which can make the cutting process a bit smoother and more predictable.

But don’t let that fool you – there’s still an art to cutting all-thread properly. You’ve got to make sure you’re using the right cutter size, applying the right amount of pressure, and keeping that blade nice and sharp. Too much force and you could end up with a burr or a jagged edge. Too little and you might not even make it through the rod.

Now, let’s talk about rebar. This stuff is a whole different animal, my friends. Rebar is typically made from much harder materials like high-carbon steel, which means it’s a lot more resistant to cutting. The threads can also be a bit more irregular and uneven, which can really throw a wrench in the works if you’re not prepared.

When it comes to cutting rebar, you’ve got to bring your A-game. You’ll need a cutter that’s specifically designed to handle the tougher material, and you’ll have to be extra careful about applying the right amount of pressure and keeping that blade in tip-top shape. Too much force and you could end up with a bent or damaged tool. Too little and you might as well be trying to cut through a block of concrete with a butter knife.

But fear not, my friends, because with the right know-how and the right tools, you can absolutely master the art of cutting both all-thread and rebar. It’s all about understanding the unique challenges of each material, and then employing the right techniques and tools to get the job done right.

Proper Sizing: The Key to Perfect Threaded Rod Cuts

Alright, now that we’ve covered the basics of threaded rod cutters and the differences between all-thread and rebar, let’s talk about the critical importance of proper sizing.

You see, when it comes to cutting threaded rods, size really does matter. And I’m not just talking about the size of the rod itself – I’m also talking about the size of the cutter you’re using.

Get this wrong, my friends, and you’re in for a world of pain. Try to cut a rod that’s too big for your cutter, and you might as well be trying to slice through a chunk of titanium with a butter knife. The blade just won’t have the power or the reach to get the job done, and you’ll end up with a mangled, uneven cut that’s going to drive you absolutely bonkers.

On the flip side, try to use a cutter that’s way too big for the rod you’re working with, and you could end up with all sorts of other problems. The blades might not be able to get a proper grip on the material, leading to a wobbly, unstable cut. Or you might end up with way too much excess material left over, which can be a real pain to clean up.

So, how do you make sure you’re using the right size cutter for the job? Well, it all comes down to careful measurement and attention to detail. Before you even think about reaching for that threaded rod cutter, you need to grab your trusty tape measure and get an accurate reading on the diameter of the rod you’ll be working with.

Once you’ve got that information, you can start scouring the market for a cutter that’s specifically designed to handle that size. Most manufacturers will clearly list the size range on the tool itself, so it’s just a matter of matching it up and making sure you’ve got the right fit.

And let me tell you, taking the time to get this right is so worth it. When you’ve got the perfect cutter for the job, the whole process becomes a breeze. The blades bite cleanly into the material, the cut is perfectly square and even, and you end up with a finished product that looks like it was done by a pro.

But trust me, trying to cut a rod that’s too big or too small for your cutter? That’s a recipe for disaster, my friends. So, measure twice, cut once, and always make sure you’ve got the right size threaded rod cutter for the job at hand.

Real-World Examples: Sizing Threaded Rods for Specific Projects

Alright, now that we’ve covered the ins and outs of threaded rod cutters and the importance of proper sizing, let’s take a look at a few real-world examples to really drive the point home.

Say you’re working on a DIY project to build a heavy-duty workbench. You know you’re going to need some serious all-thread to hold the whole thing together, so you head to the hardware store and grab a few 3/4-inch rods. Now, the question is, what size threaded rod cutter do you need to get the job done?

Well, let’s take a look. The standard 3/4-inch all-thread is going to have a diameter of, you guessed it, 3/4 of an inch. So, you’ll want to look for a threaded rod cutter that’s specifically designed to handle 3/4-inch material. Anything smaller and you’ll be fighting an uphill battle, anything larger and you might end up with way more excess material than you need.

Or let’s say you’re working on a construction site, and you need to cut some 1/2-inch rebar to size for a concrete footing. Now, rebar is a whole different beast compared to all-thread, so you’ll need to make sure you’ve got a cutter that’s up to the task. Look for one that’s rated for 1/2-inch rebar, and make sure it’s got the right kind of blade to slice through that tough, high-carbon steel.

And let’s not forget about those specialty applications, like cutting threaded rod for use in seismic retrofitting or heavy-duty industrial equipment. In cases like these, you might be dealing with some seriously beefy material, like 1-inch all-thread or even larger. That’s where you’re going to need a heavy-duty, industrial-grade threaded rod cutter that can really put the power down and make clean, precise cuts every time.

The key in all of these examples is to take the time to properly assess the size and material of the threaded rod you’ll be working with, and then match that up with the right cutter for the job. Trust me, it’s a small investment of time that’s going to pay off in a big way when you end up with a flawless, professional-looking finish.

Cutting Techniques: Mastering the Art of Threaded Rod Cutting

Alright, now that we’ve covered the importance of proper sizing and choosing the right threaded rod cutter for the job, let’s dive into the nitty-gritty of the cutting process itself. Because, my friends, there’s a real art to cutting threaded rods the right way.

Now, I know what you’re thinking – “How hard can it be to just slice through a piece of metal?” And I get it, it sounds pretty straightforward. But trust me, there’s a lot more to it than meets the eye. If you want to end up with a clean, square cut every time, you’re going to need to put in a little bit of practice and pay close attention to the details.

The first and most important step is to make sure your threaded rod cutter is properly aligned and positioned. You want the rod to be sitting squarely in the jaws of the cutter, with the blades positioned right where you want the cut to be. Any kind of tilting or misalignment can lead to a jagged, uneven cut, so take the time to get it just right.

Next, you’ll want to apply steady, even pressure as you work the handle to bring the blades together. Don’t try to rush it or force it – let the cutter do the work. If you try to cut too quickly, you could end up with a messy, burr-filled edge. Too slowly, and you might not even make it all the way through.

And speaking of burrs, that’s another critical aspect of the cutting process to keep an eye on. Threaded rods, especially the harder stuff like rebar, can sometimes leave behind little bits of ragged metal after the cut. These burrs can be a real pain to clean up, and they can even interfere with the threads if you’re not careful.

To avoid this, you’ll want to make sure you’re using a high-quality cutter with sharp, well-maintained blades. And as you’re cutting, keep an eye out for any burrs starting to form, and be ready to quickly file them down or use a deburring tool to clean things up.

Oh, and let’s not forget about safety, my friends. Cutting threaded rods can be a pretty intense process, and you don’t want to end up with any nasty cuts or scratches. Make sure you’re wearing sturdy gloves and safety glasses, and always keep a firm grip on the cutter to avoid any unexpected slipping or kickback.

But hey, don’t let all of that scare you off. With a little bit of practice and the right techniques, cutting threaded rods can be a breeze. Just take it slow, keep an eye on the details, and you’ll be cranking out perfectly-cut rods like a pro in no time.

Conclusion: Unleash Your Threaded Rod Cutting Prowess

Well, there you have it, my friends – everything you ever wanted to know about threaded rod cutters and how to use them like a true master. From understanding the different types of rods and the unique challenges they present, to mastering the art of proper sizing and cutting techniques, we’ve covered it all.

And let me tell you, once you’ve got this stuff down, the world of threaded rod projects is your oyster. Whether you’re working on a DIY project at home, tackling a big construction job, or anything in between, you’ll be able to cut those rods with precision, confidence, and a whole lot of style.

So, what are you waiting for? Grab your trusty threaded rod cutter, head to the hardware store, and let’s get to work. With the right tools and the right know-how, the possibilities are endless. Who knows, maybe you’ll even find a way to work in a shameless plug for https://powertoolspros.net/ while you’re at it.

But seriously, folks, the key is to remember that cutting threaded rods is an art form, not just a task to check off the list. Take your time, pay attention to the details, and embrace the process. Before you know it, you’ll be a threaded rod cutting maestro, leaving behind perfectly-executed, burr-free cuts that’ll make all your friends and neighbors green with envy.

So, what are you waiting for? Let’s get to work, my friends. The world of threaded rods is waiting, and it’s time to show ’em how it’s done.